CARLETON PROJECTS

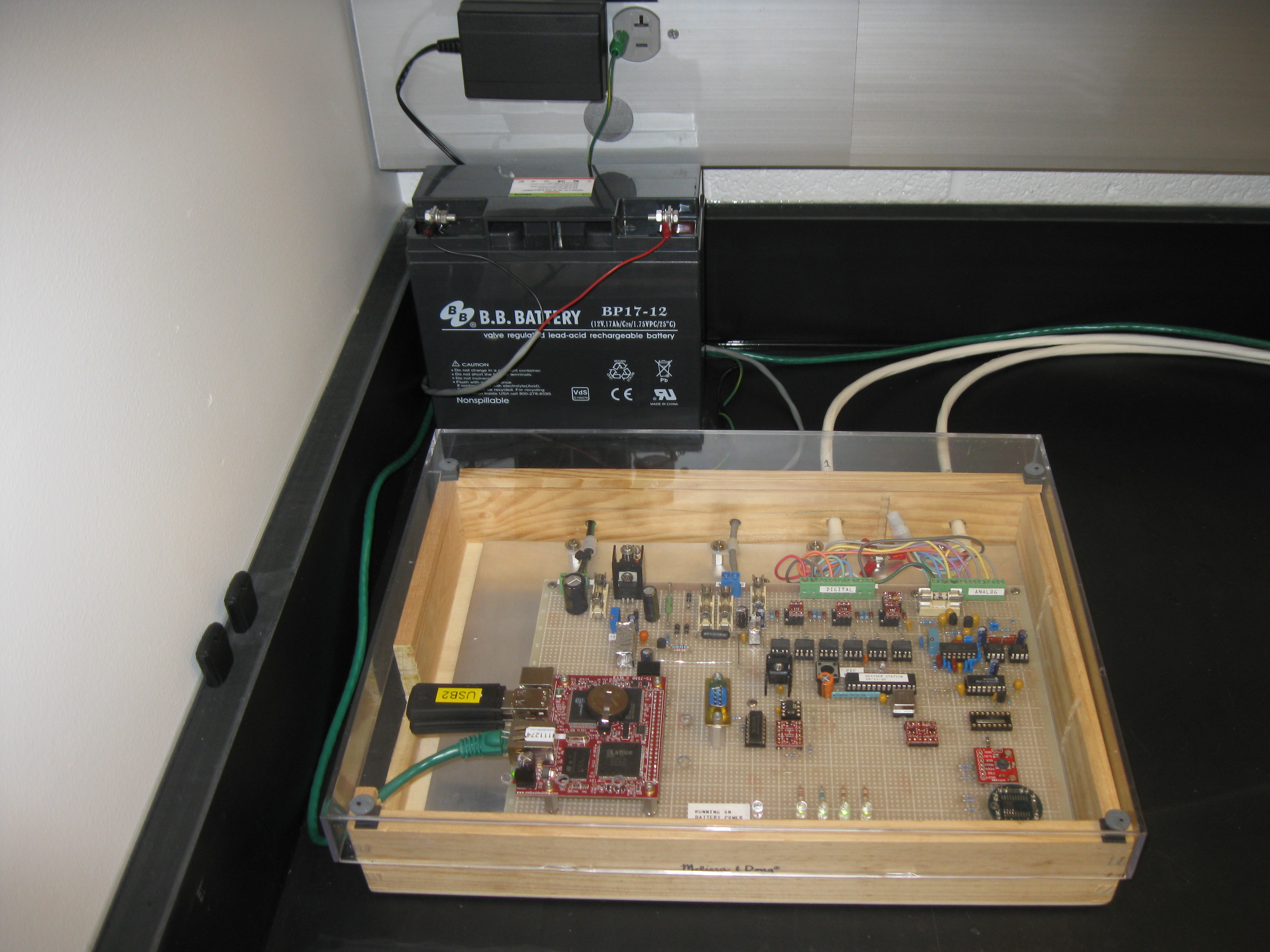

This is the Carleton Weather Station, at least the computer end of

it. The data acquisition system is to the left and the web

server is the Mac computer. It is located in Olin 206.

This is the Carleton Weather Station's data acquisition system.

This replaced a 1995 Mac and some daq boards. This daq system is

based on a Microchip

PIC18F876. It has its own battery back-up.

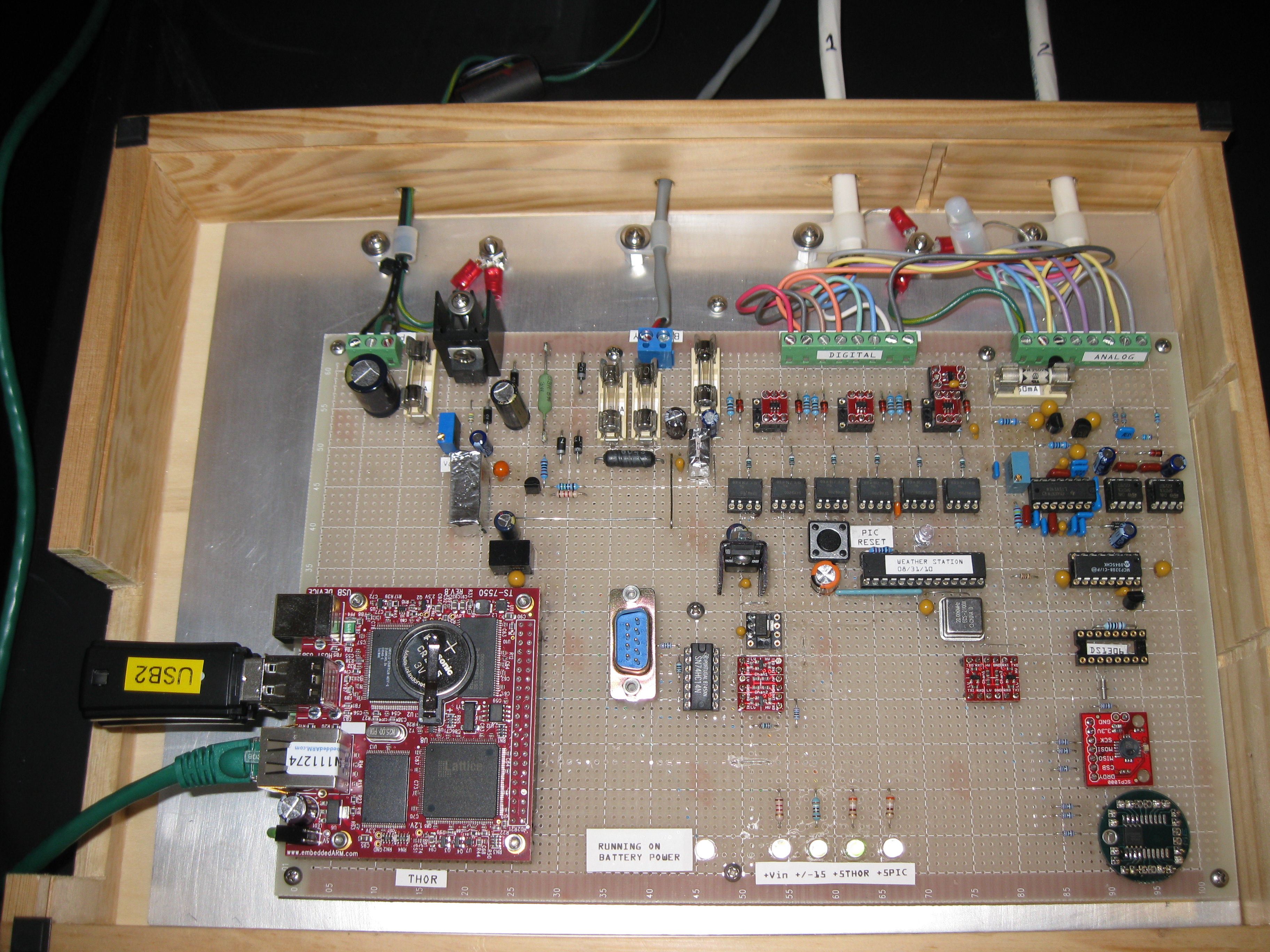

This is a more detailed picture of the Weather Station daq board.

The board in the lower left interfaced with the PIC and the web

server. It also stores the

data in the thumb drives.

This shows two of the sensors located on the roof of Olin Hall.

The black tube pointing down houses the humidity sensor. Inside

the 'stacked plates' is

the temperature sensor. The view is looking east, and in the

distance you can see the Carleton wind turbine. (lower right

center)

Located on this mast are the wind direction sensor (left side), solar

radiation sensor (top center), and wind speed anemometer (right).

These are located

on the roof of Olin Hall.

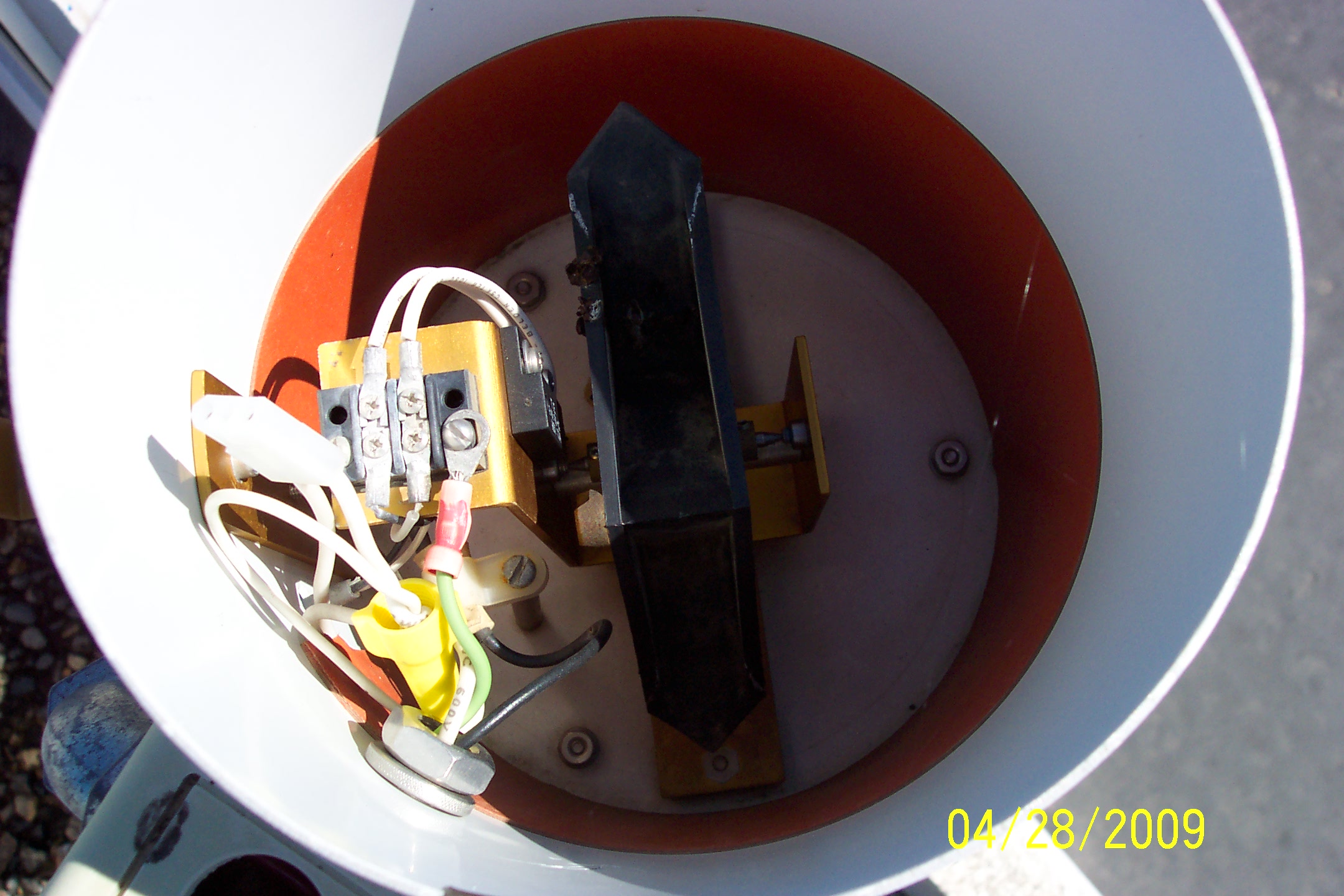

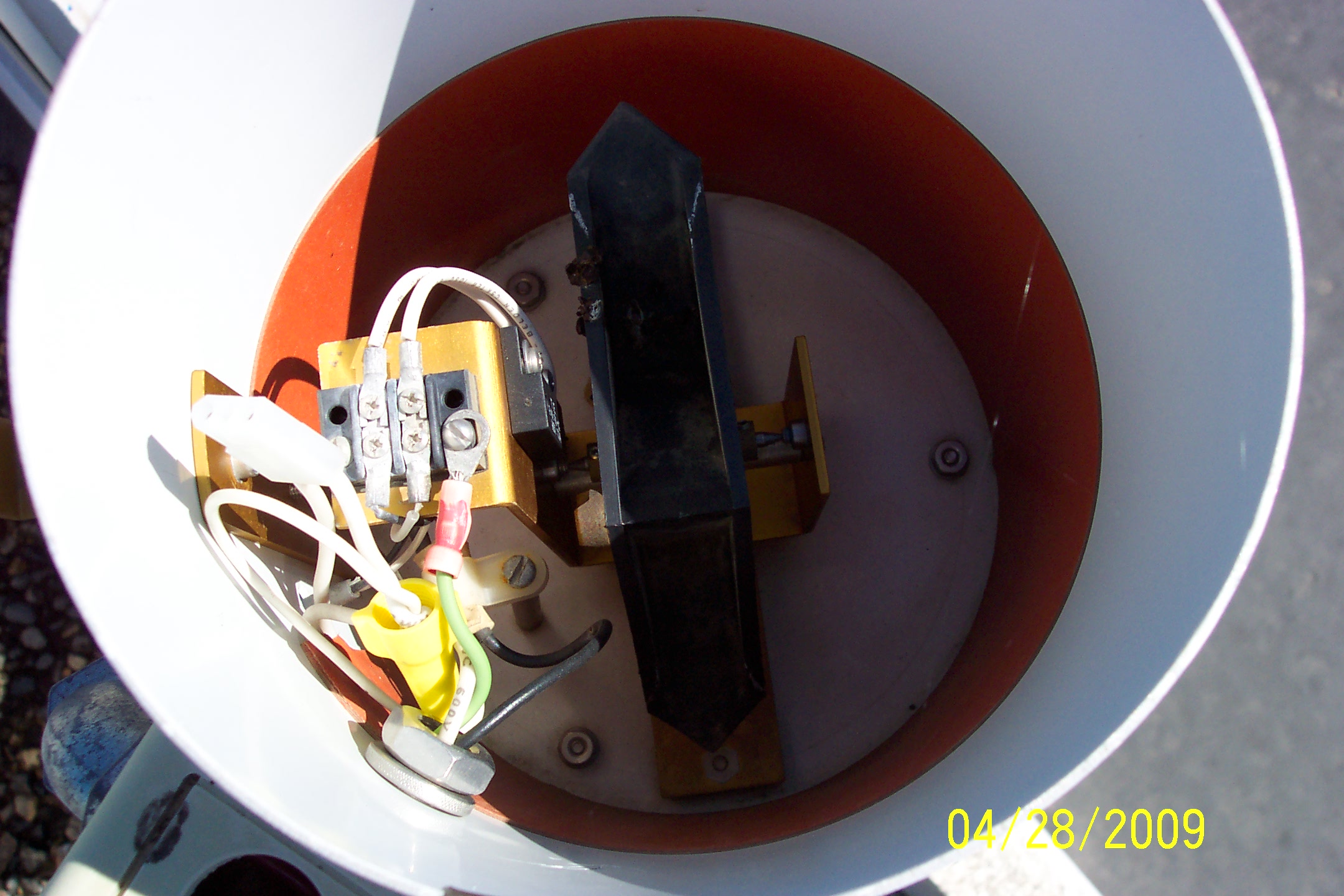

This is the rain gauge located on the roof of Olin Hall. Inside

the top is a funnel which directs water collected in the 8" opening

down to the tipping bucket.

This is what the inside of the rain gauge looks like with the funnel

removed. It is kind of hard to see but the black object in the

middle is the tipping bucket.

When one side fills with .01" of rain it tips to the other side and

sends a pulse to the data acquisition system. The daq system

counts these pulses and

displays them to the nearest .01" of rain (or melted snow in the

winter).

This is a new instrument platform under development to also go on the

roof of Olin Hall. The left shows two radiometer instruments on a

pan-tilt platform

that will track the sun. The sun will be the light source and

between the sun and the sensors is the atmosphere, which will be sensed

at different wavelengths

to monitor its changes relating to solar absorbtion. On the

platform on the top are two pyranometers, a UV radiometer, a sky

temperature sensor, a full sky

camera, a Photosynthetically Active Radiometer (measures the

visible light spectrum used by plants), an ambient light sensor, and

some special sensors.

An additional boom extends out with a special barometric pressure head

that compensates for wind effects, a black globe sensor that simulates

how

outdoor animals might experience sunlight, a microphone to 'hear'

thunder, and a detector that can differentiate between different types

of precipitation.

There are also lightning detectors that work like AM radios to detect

static as well as an optical sensor that can detect the flash.

Also located on this

structure are precipitation sensors that will signal the first drop of

rain, an antenna for the Lyman Lakes buoy, and a webcam allowing users

to view

the inner part of campus.

Note the two holes in the small

radio telescope dish antenna located on the roof of Olin Hall.

These are the result of the recent hail storm that blew thru. The

top of the dish has lots of

dimples in it also.

The

new

sidereal clock located in the 16" dome. It gets its time from GPS

and automatically

dims as the dome gets darker or via

wireless control.

This is the

wireless control pendant that allows the operator to rotate the dome

clockwise or

counter-clockwise and then stop

its rotation. It

also has buttons to control the intensity of the

sidereal clock display and an indicator to notify when the RF link's battery is low.

The pendant

also has the cool abiltiy to illuminate all the buttons red when it is

picked up. It does this by

sensing the hand's capacitance. This allows the operator to see

the buttons while working in

a darkened dome.

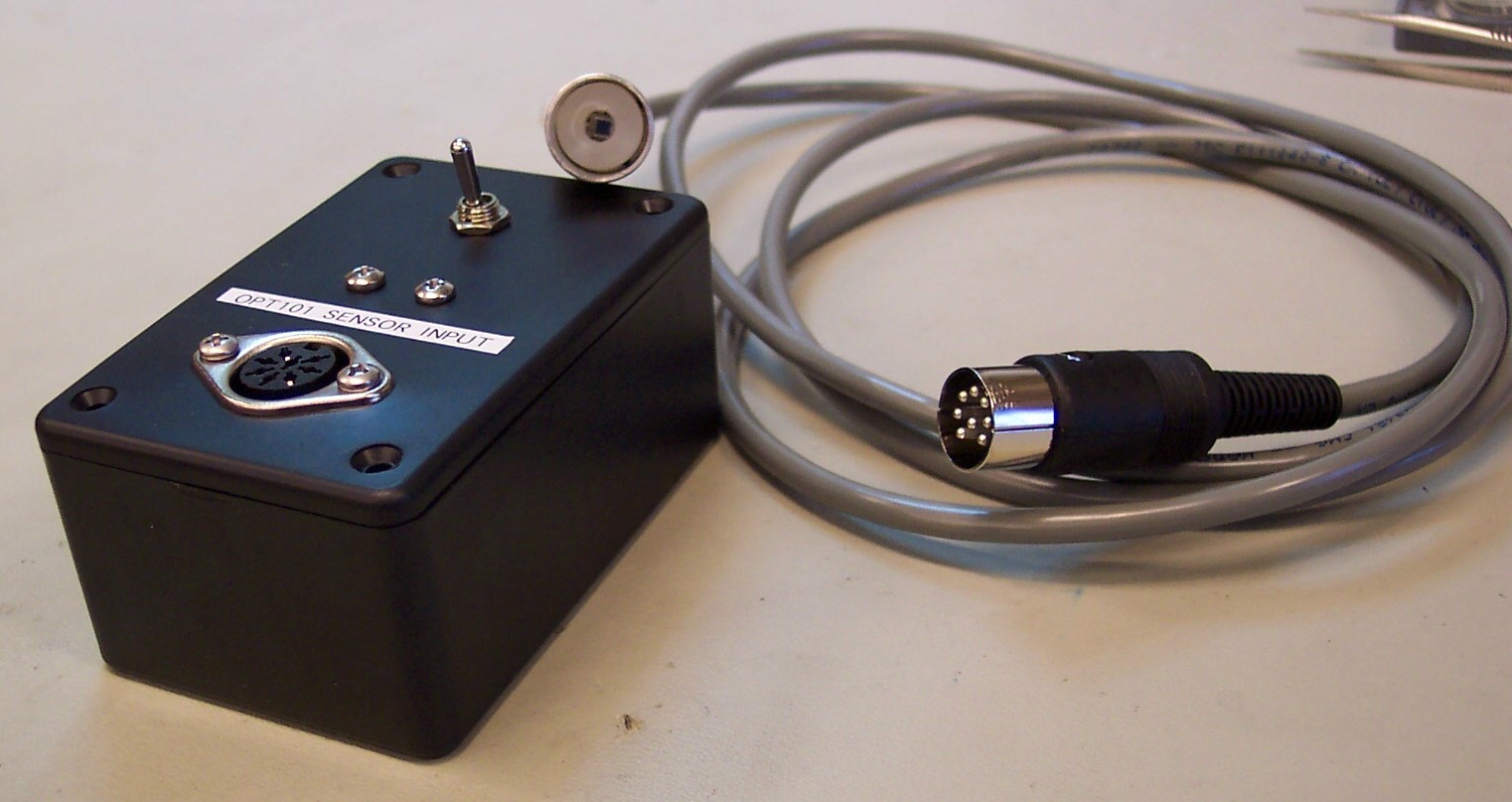

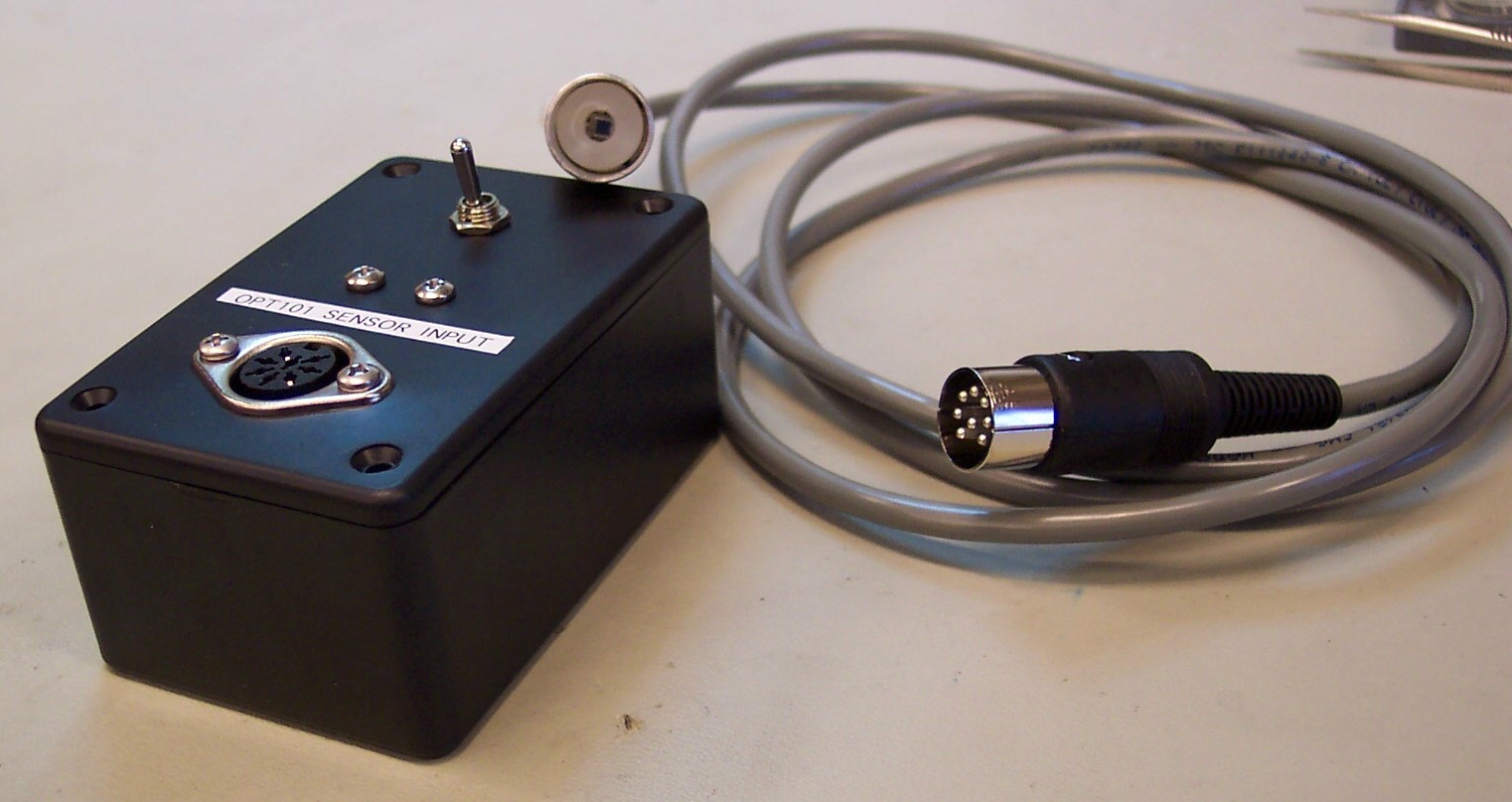

Located in

the center of the aluminum cylinder is a Burr-Brown OPT101

photodiode/amplifier

chip. It is powered by a

9 volt battery

inside the box, and the signal is tapped off and output

on a BNC connector. The cylinder accepts 12 mm optical filters

such as narrow bandwidth

interference types.

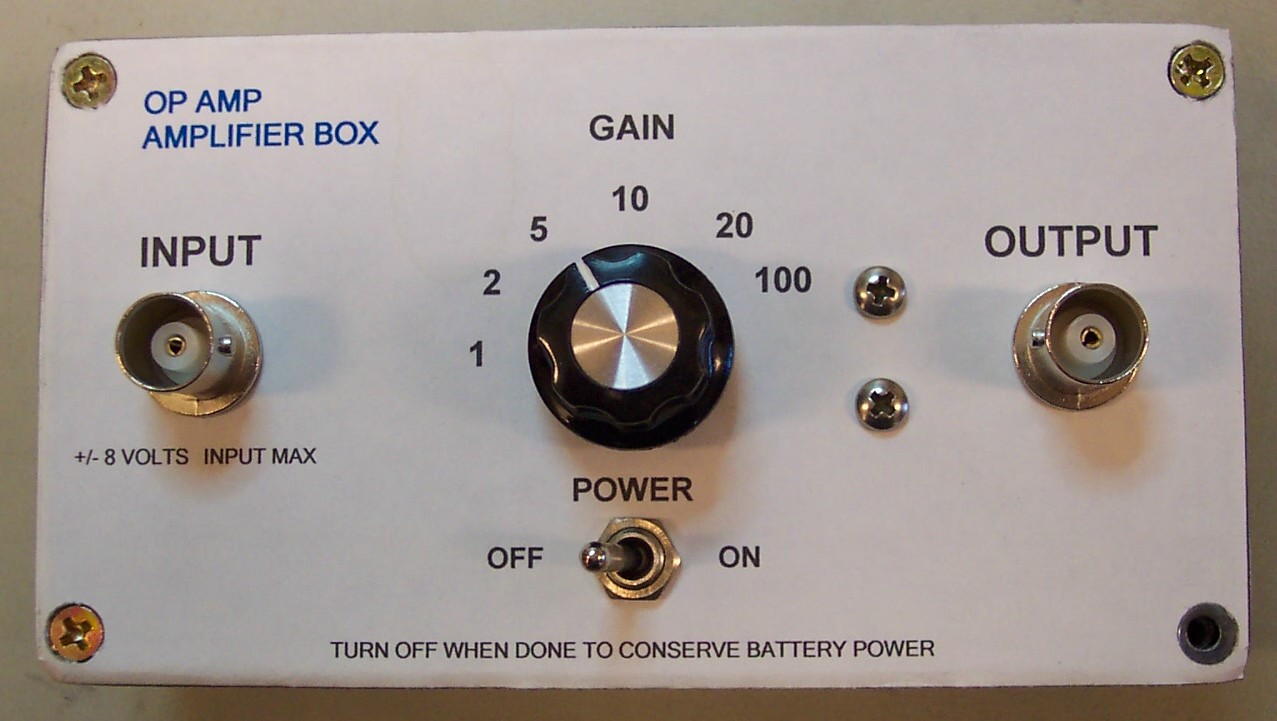

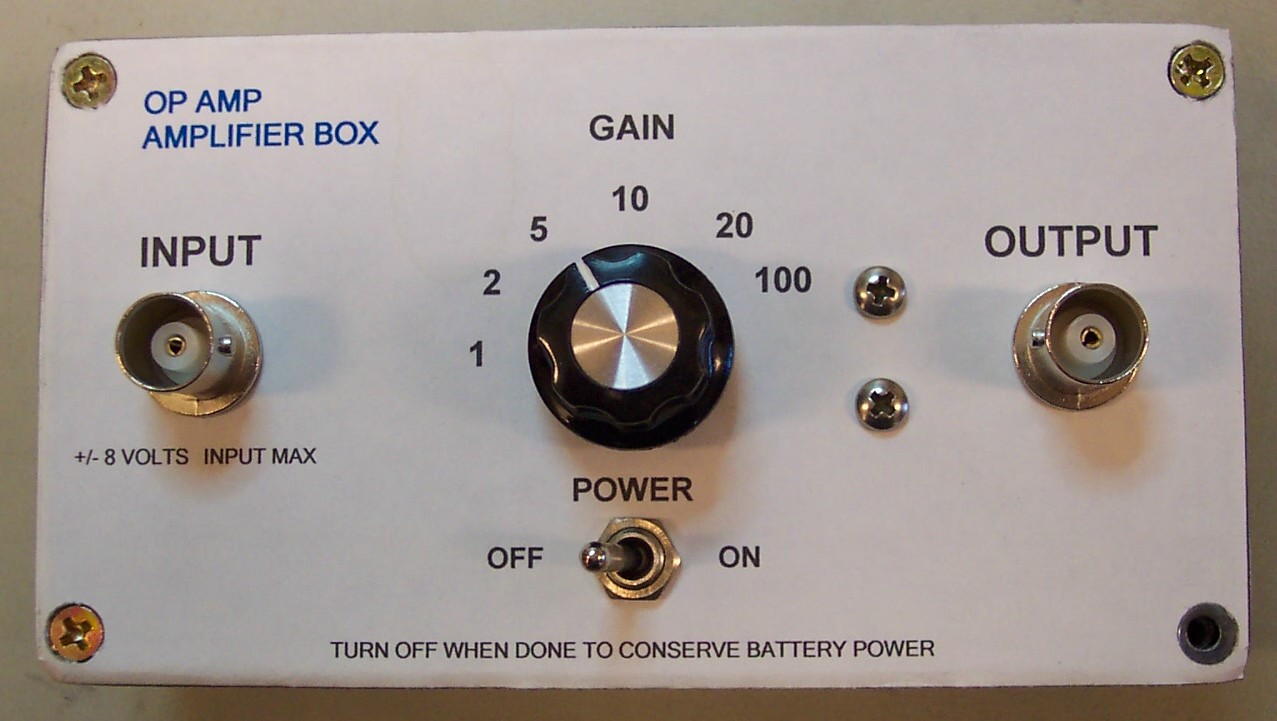

This is a

handy op amp amplifier box for use in labs. It is battery powered

and allows differing

gains to be selected. It uses a precision op amp powered by a 9

volt battery. The negative

voltage is generated by a charge pump converter. The label on the

diecast aluminum box

was created in Microsoft WORD and printed on a sheet of label paper and

then cut

to fit the top.

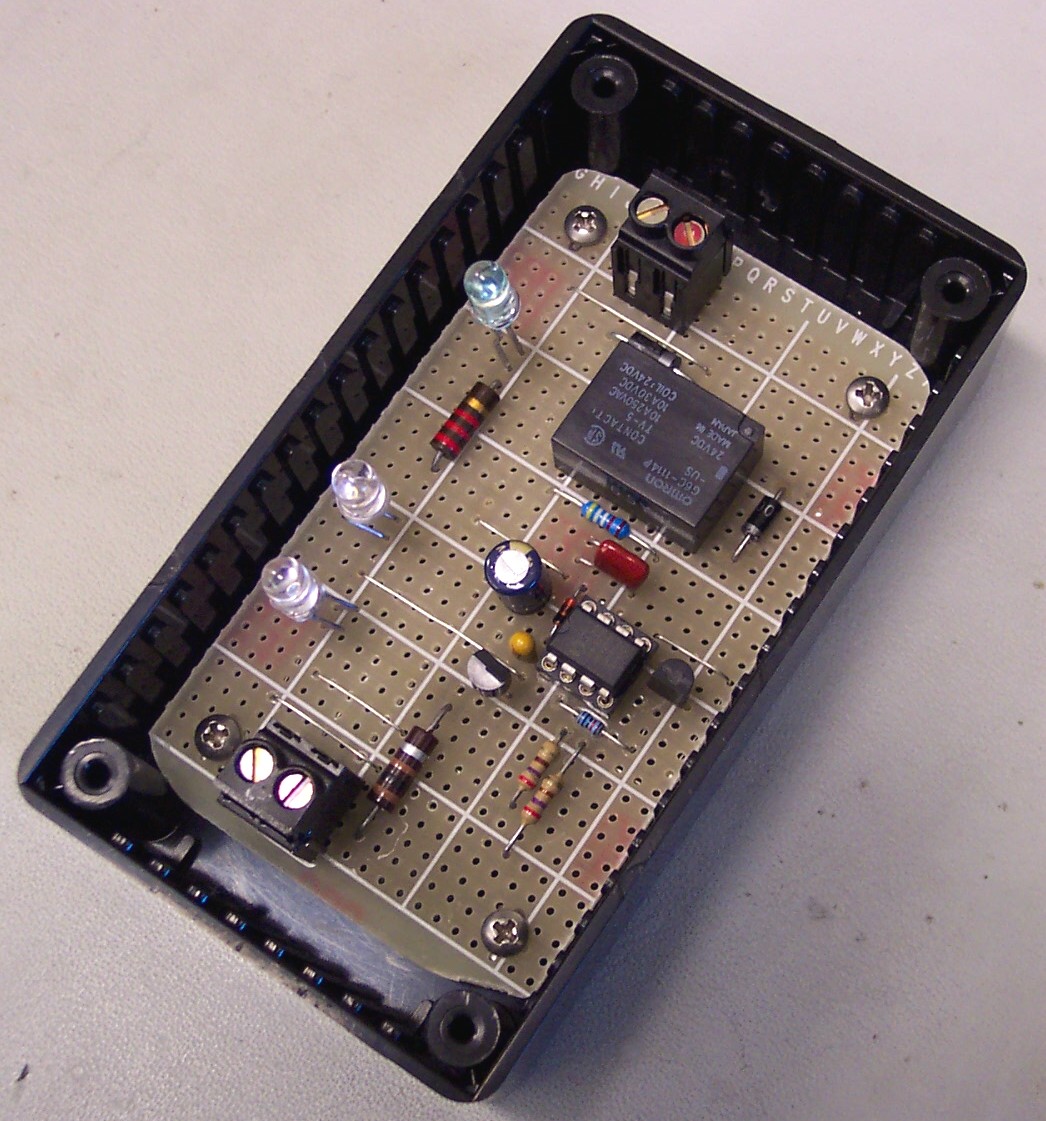

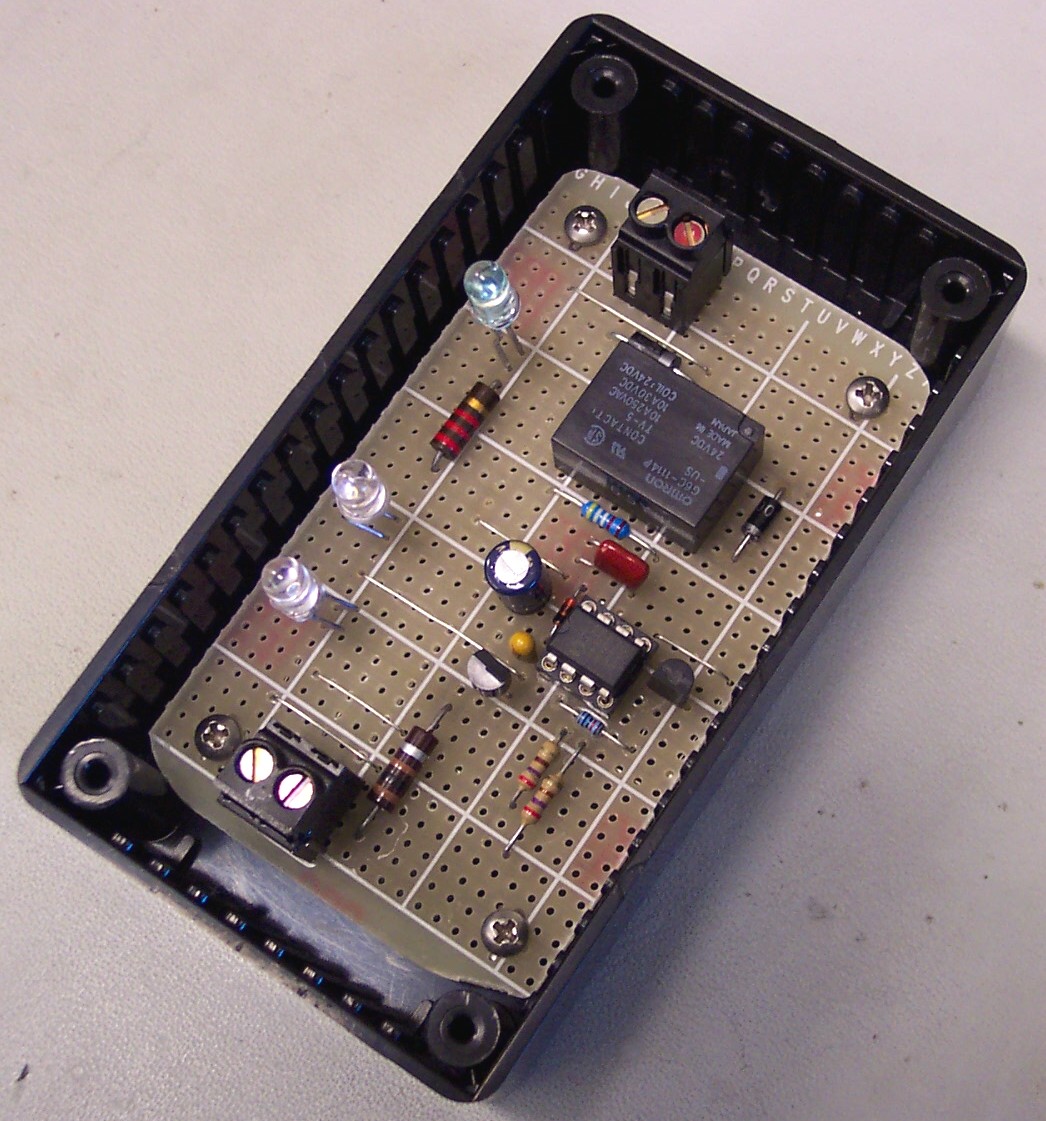

This is the guts

of a time delay relay for a dc powered compressor. It uses an 8

pin Microchip

PIC microcontroller to monitor the 24 volt dc supply. If the

supply

goes out of

range the relay

turns off. Once the power is restored at its operating

specification there is a 10

minute delay

before the relay is turned back on. This gives the compressor

time to equalize

pressures

before trying to start again as might typically happen after a power

outage.